CRACK STITCHING PROCEDURE

TOOLS & MATERIALS

| 1. Vacuum. |  |

| 2. Hammer Drill and a 3. 5/16”” diameter x 6” long drill bit. |

|

| 4. Scraper or Razor Knife |  |

| 5. Dual Cartridge Gun |  |

| 6. Road Ware 10 Minute Mender – Gray |  |

PREPERATION AND INJECTION PROCEDURES

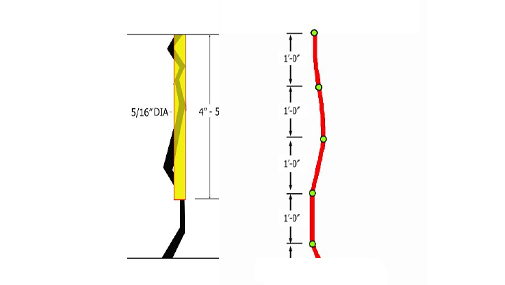

1. Using a 5/16” diameter bit, drill 4” – 5” deep holes @ 12” O.C.

Note: When drilling, allow the drill bit to follow the crack, the drill may tilt if the crack is not plum, this ensures the repair material is installed at the centerline of the crack at each hole.

2. Vacuum the repair.

3. Inject 10-minute mender.

4. Fill completely leaving slightly high.

5. Shave off excess with a Razor Knife.

Note: Prior to repairing, observe all the surrounding saw cuts for signs of activation, if it is determined that surrounding joint or joints have not activated chase the joint a minimum of 4” deep prior to performing this procedure.