Minimizing Traffic Disruption and Extending the Bridges

Minimizing Traffic Disruption and Extending the Bridges

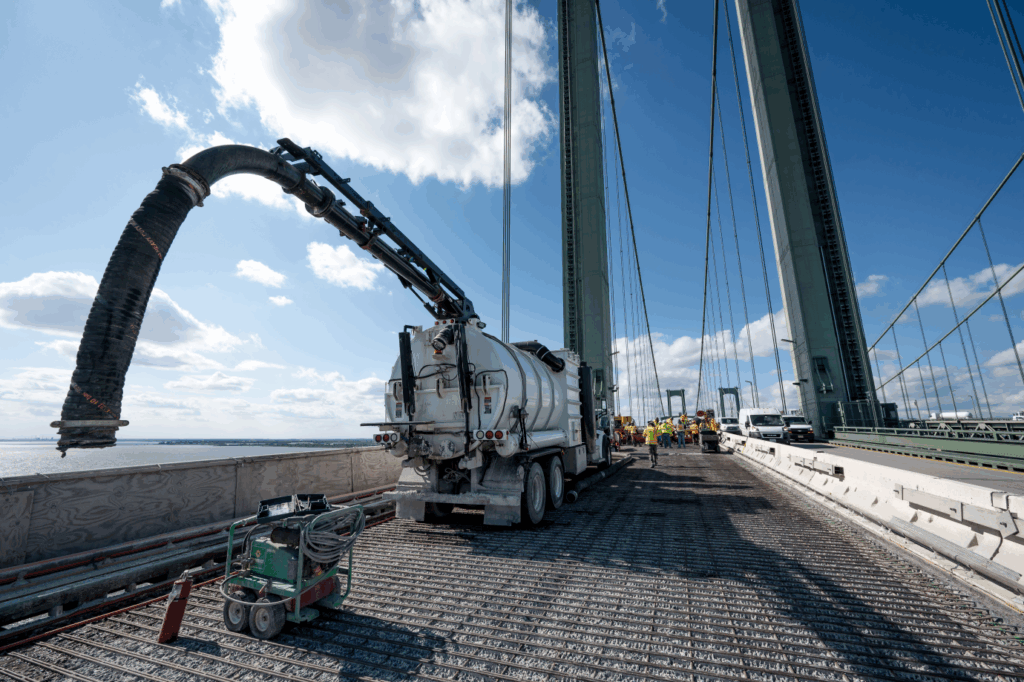

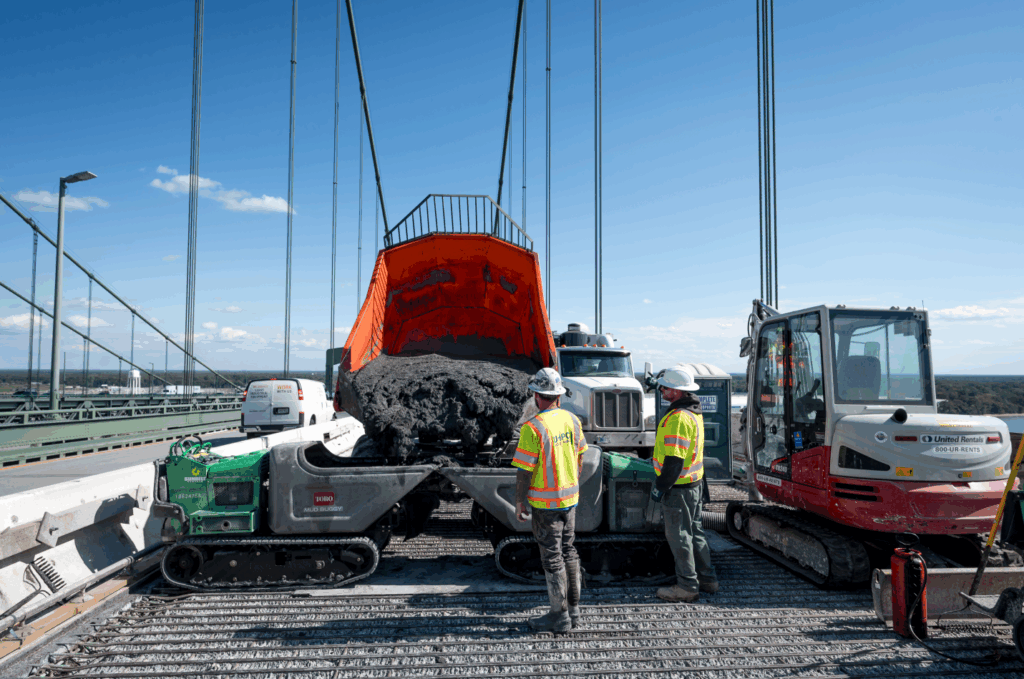

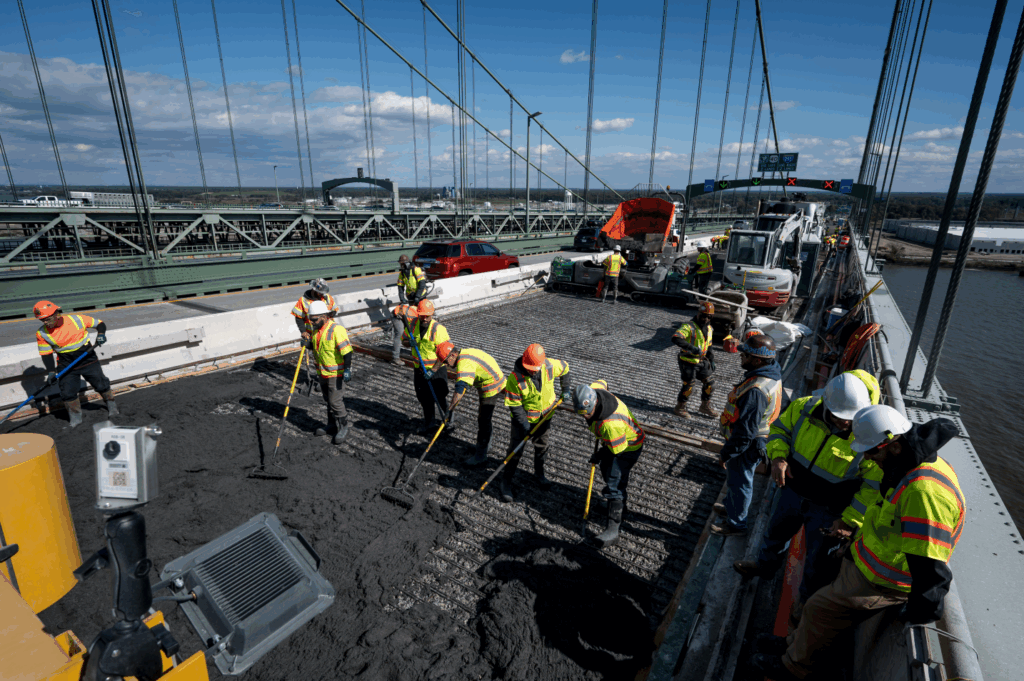

The Delaware Memorial Bridge, a critical transportation corridor linking Delaware and New Jersey, faced mounting structural concerns after more than six decades of continuous service. With over 80,000 vehicles crossing daily, the bridge’s northbound deck required urgent rehabilitation to extend its lifespan and ensure safety. However, the project posed significant logistical challenges. Construction activities had to be scheduled during narrow time windows when traffic volumes were lower, minimizing disruption to commuters and toll operations. Additionally, the solution needed to reinforce the aging deck without adding substantial weight, which could compromise the structural integrity of the twin suspension bridges, each spanning two miles across the Delaware River.

Chryso Admixtures Powering Ultra-High Performance Concrete (UHPC)

To meet these constraints, the Delaware River & Bay Authority (DRBA) conducted a life-cycle cost analysis and selected Ultra-High Performance Concrete (UHPC) as the optimal repair method. UHPC is a highly durable and fiber-reinforced material known for its exceptional strength and longevity. Unlike traditional concrete overlays, UHPC requires a thinner application, which reduces the overall weight added to the structure while delivering superior performance. This made it an ideal choice for the bridge’s rehabilitation, allowing the team to preserve the existing deck while enhancing its load-bearing capacity and resistance to environmental stressors.

The UHPC overlay system was installed in three phases beginning in September 2022, following a successful pilot program in 2020. Each phase involved the removal of two to three inches of deteriorated concrete from the deck surface and its replacement with an equivalent thickness of UHPC. This approach not only addressed the structural deficiencies but also provided a protective layer that would extend the deck’s service life by more than 50 years. The admixtures supplied by Chryso North America played a critical role in enabling the UHPC to be mixed, placed and cured efficiently within the tight construction windows. The advanced admixture formulations ensured consistent performance and workability, even under challenging site conditions, helping crews maintain pace and quality throughout the project.

Project Highlights

5,000

cubic yards of ultra high performance concrete (uhpc)

> 18,000

psi compressive strength which is more than 3x stronger than traditional bridge deck concrete

80,000

vehicles crossing per day

11

weeks shaved off the project schedule

$100 Million Dollars

savings resulting from a 75 year extended life span

The Results

The Delaware Memorial Bridge rehabilitation was completed in November 2023, marking the successful conclusion of a two-year effort to modernize one of the region’s most vital infrastructure assets. The use of UHPC and Chryso’s admixtures resulted in a significantly more durable bridge deck, capable of withstanding heavy traffic loads and harsh weather conditions for decades to come. The project avoided the need for full-depth deck replacement, which would have required longer closures and higher costs, and instead delivered a high-performance solution that preserved the bridge’s structural integrity while minimizing disruption to daily operations.

Beyond its technical achievements, the project has been recognised for its innovation and sustainability. By leveraging UHPC and advanced admixture technology, the team was able to reduce material usage, lower carbon emissions and expedite construction timelines.

The final phase, completed in September 2023, involved rehabilitating the two right lanes on the New Jersey side of the northbound bridge, demonstrating the scalability and efficiency of the chosen approach.

The success of this project sets a precedent for future infrastructure upgrades across the country, showcasing how modern materials and strategic planning can overcome complex engineering challenges while delivering long-term value.

ENR Best Project Award Winner

The Delaware Memorial Bridge rehabilitation project showcased the pivotal role of Chryso admixtures in delivering a durable and sustainable solution using Ultra-High Performance Concrete (UHPC). Faced with the challenge of maintaining traffic flow on a vital toll bridge that sees over 80,000 vehicles daily, the Delaware River & Bay Authority opted for UHPC overlays to strengthen and protect the aging deck without adding structural weight.

The future of UHPC in construction is bright

“The greater strength with less material needed and longer service life of more than 50 years, makes UHPC a key component in the sustainability goals of the construction industry. The use of UHPC on the Delaware Memorial Bridge deck rehabilitation project was the perfect fit, offering speed and light-weight durability. We were pleased to apply our admixture technologies to customize the UHPC, so that it met all performance needs and ensure that it will stand the test of time.”

Steve Williams, President Construction Chemicals

Project Participants

Project: Delaware Memorial Bridge Deck

Owner: Delaware River & Bridge Authority

Designer / Structural Engineer: WSP

Ready-Mix Producer: UHPC Solutions North America

Concrete Contractor: UHPC Solutions North America

UHPC Material Supplier: Ductal US

Concrete Mix and Specifications:

Greater than 18,000 PSI for UHPC for Bridge Deck

Volume: 5,000 total cubic yards