Supporting a Unique Commercial Building

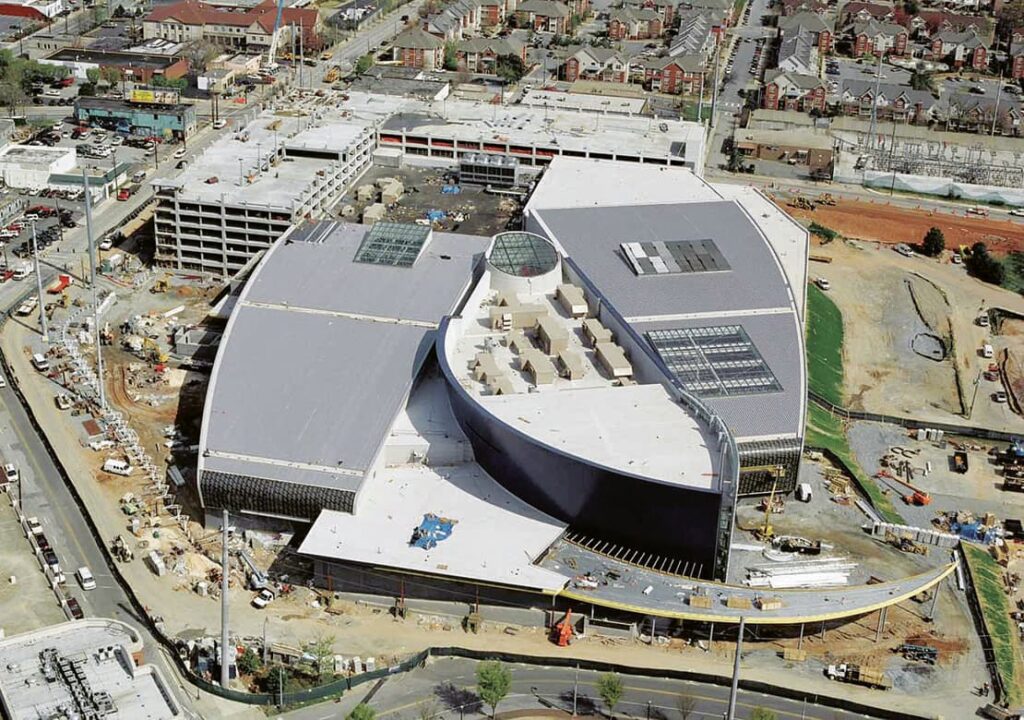

The Georgia Aquarium is the largest aquarium in the Western Hemisphere, with 10 million gallons of fresh and marine water and tens of thousands of animals. Designed to look like a modern Noah’s Ark, the new Georgia Aquarium draws 2.2 million visitors a year. The imposing facility includes more than 505,000 square feet of space, housing more than 100,000 animals in eight million gallons of fresh and saltwater.

Finding Highly Resistant Concrete Solutions

The Georgia Aquarium’s concrete viewing tanks are among the largest in the world—33′ tall, with 4′ thick walls at the base. These walls have many pipe insets, and the tanks themselves contain saltwater.

The concrete supplier, Lafarge North America, therefore had to deal with congested forms that required long-term corrosion resistance. Lafarge developed a close working relationship with our team in order to meet these challenges head on.

Creating High-Strength Concrete

To deliver high-strength concrete in highly congested forms, Lafarge added ADVA® superplasticizer to its proprietary self-consolidating concrete mixture, AGILIA®. The self-consolidating concrete moved easily through the congested forms, while the AVDA® superplasticizer delivered strengths above 8000 psi—33% over design specifications.

Our DCI®-S corrosion inhibitor was also incorporated into the mixture to prevent corrosion from saltwater, and extends the lifecycle of concrete exposed to marine environments.

In addition, STRUX® 90/40 Synthetic Macro Fiber reinforcement was used for secondary reinforcement in slab-on-ground concrete throughout the structure, including concrete walkways, areas near the tanks, and other high traffic locations. Compared to other types of reinforcement, STRUX® is safer to use, reduces the potential for damage to waterproofing materials placed under the concrete, and eliminates the risk for corrosion.

The contractor noted that the STRUX® fibers’ ease of handling helped his company maintain their schedule, allowing the aquarium to open on time.

The use of STRUX® for high-traffic walkways and DCI®-S for the tanks extended the lifecycle of the concrete in these areas, allowing the museum to save on maintenance in the long term. Similarly, the use of ADVA® superplasticizer ensured that the pipe inset areas of the tanks would remain intact under the highest strains.

John Brett, Commercial Project Manager for Lafarge Commercial Project manager John Brett says “The mixes have performed very well, and we have been able to adapt quickly to the fast-changing demands of this project.”

“The aquarium was one of our more demanding projects, because of its scope and unusual features and structural elements… timing and communication were crucial, and we did a very good job of both.”

– Kirk Deadrick, Director of Quality Assurance. Lafarge North America

Project Participants

Concrete Supplier Lafarge North America, Atlanta, GA

Contractor Brasfield & Gorrie, Atlanta, GA

Structural Engineer Uzun and Case Engineers, Atlanta, GA

Architect Thompson, Ventulett, Stainback & Associates, Inc. (TVS), Atlanta, GA

Owner Representative Heery International, Atlanta, GA