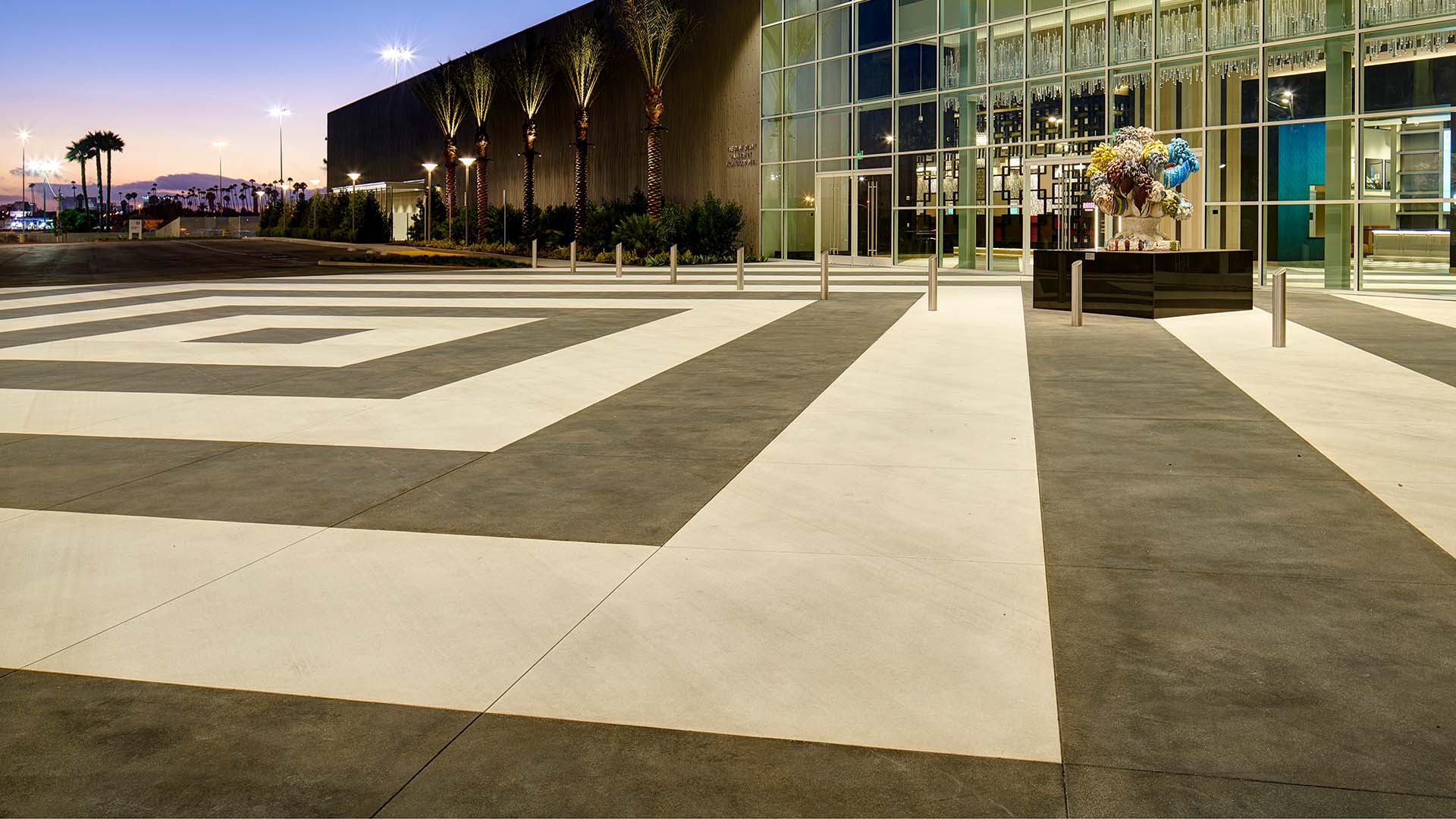

Functional & Decorative Concrete Surfaces

TOP-CAST® Decorative Solutions help achieve an architectural finish with an exposed aggregate look. Our products are more than just a surface retarder — it’s a surface retarder that’s optimized for robust, consistent performance in all temperature and weather conditions. TOP-CAST® will create perfect, eye-catching flatwork that will satisfy both contractors and customers.

With our TOP-CAST® SS 100, you get a water-soluble surface protectant that prevents splatter and other materials from adhering to surrounding surfaces during concrete operations, eliminating the need for plastic barriers.

In twelve different specified depths, our TOP-CAST® Series (01-250) produces effects ranging from a barely-there acid-washed sheen to a stony look. TOP-CAST® Series (01-250) is color-coded, so the appropriate etch depth is easy to identify by contractors.

Products

Top-Cast® Series (01-250)

Top-Cast® SS 100

Benefits of Using TOP-CAST®

Sublime Ease-of-Use for Poured-in-Place Concrete

Stands Up to the Elements

In addition, the surface retarder is designed to be extremely stable and robust, with the ability to resist temperatures of up to 150°F. Ambient temperatures can affect finishing, application, and surface paste removal.

Fire-and-Forget Technology

For example, TOP-CAST® is color coded so the appropriate etch depth is easy to identify by contractors.

The product will retard to a certain depth, and then deactivate on its own, leaving contractors free to concentrate on other issues.

Nationwide Availability

Available at local building supply stores, TOP-CAST® has twelve different specified depths to produce effects ranging from a barely-there acid-washed sheen to a stony look that’s 1 ¼ inch deep.

Each variant is color-coded, making it easy to use the right depth and avoid mistakes.